This study compares two production pathways for ammonia with low sulphur fuel oil (VLSFO) used as fuel in shipping. The ammonia is produced through the Haber‐Bosch process, where nitrogen (N2) and hydrogen (H2) are combined into NH3. The main difference between the two ammonia production pathways lies in the H2 production, as the H2 can be from natural gas (CH4) in combination with carbon capture and storage (CCS) or via electrolysis of water (H2O) with renewable electricity sources. Within the industry, the two pathways are often called ‘blue’ and ‘green’ ammonia.

Ammonia must be ignited by a pilot fuel, which is assumed to be VLSFO, and the study therefore compares 1 MJ of ammonia, where VLSFO accounts for 9.6% of the total fuel energy of 1 MJ ammonia, with 1 MJ of VLSFO. Throughout the report, the share of VLSFO as a pilot fuel needed to ignite ammoni a is referred to as ‘ammonia with 9.6% e/e VLSFO’.

The LCA includes all life cycle stages from cradle to grave of ammonia fuel and VLSFO, i.e., production of fuel feedstock, fuel production, distribution and bunkering, as well as storage and combustion on board of the ship. This system boundary is often referred to as ‘well-to-wake’ (WtW).

The report includes two modelling approach: a consequential model and an attributional model aligned with the revised version of the Renewable Energy Directive (RED II) guidelines for renewable fuels of non-biological origin (RFNBOs).

This report is commissioned by A.P. Moller – Maersk and internal quality assurance has been ensured by inviting several relevant stakeholders to take part in the project scoping, data collection, and review of methods and assumptions. While the partners have contributed to validating the technical aspects, they have not participated in the interpretation of the results.

The project partners include: A.P. Moller – Maersk, Environmental Defense Fund Europe, Nippon Yusen Kabushiki Kaisha, CMA CGM, DFDS A/S, American Bureau of Shipping, MAN Energy Solutions, Svitzer A/S and Havenbedrijf Rotterdam N.V.

Appendix 9 – Marginal electricity mixes

Appendix 11 – Final review statement and itemized review report

Download full report here:

Our collaboration with Arla began in 2011 with a carbon footprint of Arla’s milk production in Denmark and Sweden. This work has since expanded and been updated through several iterations into an advanced dairy LCA model. Arla uses this model for baselines and benchmarks of its sustainability goals, as well as a tool for individual farmers to understand where their emissions originate.

Today, the dairy LCA model powers Arla’s FarmAhead™ Check tool, which enables 7,986 farmers across seven European countries to calculate the exact GHG footprint of 1 kg of raw milk from their specific farm.

The tool accounts for over 200 farm inputs, including cow feed, fertiliser use, cattle breeds, manure treatment technologies such as biogas, and energy and fuel consumption. These inputs are combined in the LCA model to produce a farm-specific carbon footprint of the milk.

We continuously update and maintain the LCA model to improve the level of detail in the background data and models, as well as incorporating the best techniques for mitigating GHG emissions in milk production.

This design offers Arla full transparency and data autonomy.

The FarmAhead™ Check tool allows Arla to monitor the progress of its climate strategy and assist farmers in reducing emissions by spotting the most effective reductions.

81% of Arla’s total corporate emissions come from its farmers,[1] and the LCA tool provides unprecedented data transparency into where the emissions originate and how top-performing farmers can lead the way for others to do the same.

By 2022, 99% of Arla’s owner milk volume had been assessed by the FarmAhead™ Check tool. The tool makes it possible for Arla to create a data driven and personalised action plan for each farmer to reduce their climate footprint even further.

Our model includes new GHG mitigation technologies as they become relevant for the farmers, including manure acidification and nitrification inhibitors.

[1] https://www.arla.com/49b894/globalassets/arla-global/sustainability/climate-ambition/arla-climate-ambitions-2030-and-2050-2023.pdf p. 7

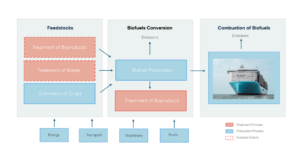

Maersk has committed to a new fleet of dual-fuel vessels capable of running on alternative fuels like methanol, but sourcing the amounts of fuel needed to power them is no easy task. To inform their fuel strategy, Maersk needed to track the environmental performance of five different biofuels to compare and benchmark their sustainability.

The production of biofuels involves the use of land, feedstocks such as waste, crops or by-products, and large amounts of energy. This means that greenhouse gas (GHG) emissions and environmental impacts can vary significantly between biofuels, depending on what the fuel is made from, how it is processed and treated, and how much land was used in the process.

To achieve the flexible decision support required by Maersk, we delivered an LCA tool modelling the cradle-to-grave impacts of five different biofuels. The tool enables Maersk to consider different production pathways, feedstock inputs and regional markets where the fuel is produced, and to benchmark the GHG and non-GHG impacts from all combinations.

The LCA tool enables Maersk to determine the environmental impacts of any specific biofuel production. Because Maersk’s demand for renewable fuels is so significant, the project also included an estimation of the scalability and availability of each biofuel feedstock. This gives Maersk the market insight needed to choose the most sustainable and economically feasible renewable fuel solution.

Overall, the project gives Maersk unprecedented transparency into the climate risks, land-use change risks, and overall environmental sustainability performance of five biofuel alternatives in real time.

The project included a review of the LCI data currently available in the ecoinvent database for platinum group metals (PGM), a literature review on PGM production by mines worldwide, a market analysis on PGM supply and demand, the identification of the determining product and dependent co-products in each mine, as well as generating LCI datasets for a total of five metals: palladium, platinum, rhodium, iridium and ruthenium, using the ecoinvent database as background.

This report presents a summary of a detailed life cycle assessment (LCA) study of palm oil production at United Plantations Berhad (Teluk Intan, Malaysia). LCA is a technique to assess environmental impacts associated with all the life cycle stages of a product or service from ‘cradle to grave’. The current study is a desk‐study performed on the distance, carried out January to March 2024, and it builds on top of six other large studies carried out for United Plantations in 2008, 2011, 2014, 2017, 2020, and 2023. The study in 2008 was the first LCA of palm oil ever, which is fully compliant with and critical reviewed according to the international standards on LCA: ISO 14040 and 14044.

The environmental impact of palm oil is presented as greenhouse gas (GHG) emissions, i.e. carbon footprint, as well as for a number of other impact categories such as biodiversity, respiratory effects and toxicity. The environmental impacts relate to the life cycle of palm oil from cultivation to the gate of the refinery, including all upstream emissions, e.g. from the production of fertilisers, fuels and machinery. The results are shown per kg of refined palm oil, as well as for United Plantations total product portfolio (corporate GHG footprint).

Over the last decades, United Plantations Berhad has worked intensively in reducing their environmental impacts. The effect of this work is illustrated by tracking the carbon footprint for the company’s production of palm oil from 2004 to 2023.

The primary purpose of the LCA is to document and assess the environmental impacts from the production of palm oil at United Plantations Berhad. Secondly, the purpose is to follow over time the GHG emissions from the production of palm oil at United Plantations Berhad. Thirdly, to quantify the absolute impact of United Plantations’ product portfolio, fourthly, to compare United Plantation’s production of palm oil with average Malaysian/Indonesian palm oil and other major vegetable oils, and fifthly, to analyse improvement options for United Plantation’s production of palm oil.

A baseline climate footprint of the Danmarks Idrætsforbund (DIF) for the year 2019 was calculated through an Organisational Life Cycle Assessment performed by LCA 2.-0 consultants using foreground data from 2019 delivered by DIF in 2022. That part of the project was completed in October 2022. The updated climate footprint for the year 2022 was calculated using foreground data from 2022 delivered by DIF in 2023.

The results of the projects can be used to identify climate impact hotspots and the most relevant options for reducing this impact.

The LCA tool makes it possible for horticultures in Denmark to calculate the environmental impacts from each crop. The intended application for Danish Horticulture (Dansk Gartneri), was to identify impacts and hotspots and use the outcome to substantiate their ongoing work on reducing the impacts from the Danish horticultural production. The tool is prepared for both organic and conventional cultivation practices. Furthermore, there are both greenhouse and free range production methods included.

The horticulture-specific calculator includes impacts for the production and upstream in the life cycle, including relevant processing and packaging. Results are given per ton crop at the greenhouse gate using Stepwise as method or as impacts pr. hectare or as a total for each holding studied.

This project is representative of the type of tools we customise for the our clients, who want multiple producers within the same sector to get reliable and accurate impacts for their individual production. Hence, the results are useful for decision making in future strategies and goals for each primary producer as well as the organisation, Danish Horticulture.

LCA is a technique to assess environmental impacts associated with all the life cycle stages of a product or service from ‘cradle to grave’. Over the last decade, United Plantations Berhad has worked intensively to reduce their environmental impacts and this ongoing project is part of the underlying research.

The primary purpose of the project is to document and assess the environmental impacts from the production of palm oil at United Plantations Berhad. Secondly, the purpose is to follow over time the GHG emissions from the production of palm oil at United Plantations Berhad. Thirdly, to compare United Plantation Berhad’s production of palm oil with average Malaysian/Indonesian palm oil and other major vegetable oils, and fourthly, to analyse improvement options for United Plantation Berhad’s production of palm oil.

This project currently consists of eight studies carried out for United Plantations Berhad in 2008, 2011, 2014, 2017, 2019, 2020, 2021 and 2022. The study in 2008 was the first LCA of palm oil ever, which was fully compliant with and critical reviewed according to the international standards on LCA: ISO 14040 and 14044.

The environmental impact of palm oil is presented in the reports as greenhouse gas (GHG) emissions, i.e. carbon footprint, as well as for a number of other impact categories such as biodiversity, respiratory effects and toxicity. The environmental impacts relate to the life cycle of palm oil from cultivation to the gate of the refinery, including all upstream emissions, e.g. from the production of fertilisers, fuels and machinery.

Recent reports:

LCA of palm oil at United Plantations Berhad 2023 (Results 2004-2022)

LCA of palm oil at United Plantations Berhad 2022 (Results 2004-2021)

LCA of palm oil at United Plantations Berhad 2021 (Results 2004-2020)

LCA of palm oil at United Plantations Berhad 2020 (Results 2004-2019)

LCA of palm oil at United Plantations Berhad 2019 (Results 2004-2018)

LCA of palm oil at United Plantations Berhad 2017 (Results 2004-2016)

LCA of palm oil at United Plantations Berhad 2014 (Results 2004-2013)

This report presents a detailed cradle-to-consumer life cycle assessment (LCA) screening of fish products sold by Kangamiut Seafood products. Kangamiut Seafood is a trading company and is not directly involved in fishing operations, however the activities of their suppliers and other affected systems are included in the product life cycles. In addition, carbon offsetting potential for Kangamiut Seafood is included as part of the assessment. The study covers a wide range of environmental impacts, including greenhouse gas (GHG) emissions (i.e. carbon footprint), nature occupation, respiratory effects, eutrophication etc. The LCA addresses both direct land use changes (dLUC), indirect land use changes (iLUC), and in connection makes use of recent developments in land use changes (LUC) modelling to include GHG emissions. The primary focus is on GHG emissions. The LCA model has a flexible design, which allows future updates, such as calculating results every year in the future, to be carried out with a minimum of extra work.