This study compares two production pathways for ammonia with low sulphur fuel oil (VLSFO) used as fuel in shipping. The ammonia is produced through the Haber‐Bosch process, where nitrogen (N2) and hydrogen (H2) are combined into NH3. The main difference between the two ammonia production pathways lies in the H2 production, as the H2 can be from natural gas (CH4) in combination with carbon capture and storage (CCS) or via electrolysis of water (H2O) with renewable electricity sources. Within the industry, the two pathways are often called ‘blue’ and ‘green’ ammonia.

Ammonia must be ignited by a pilot fuel, which is assumed to be VLSFO, and the study therefore compares 1 MJ of ammonia, where VLSFO accounts for 9.6% of the total fuel energy of 1 MJ ammonia, with 1 MJ of VLSFO. Throughout the report, the share of VLSFO as a pilot fuel needed to ignite ammoni a is referred to as ‘ammonia with 9.6% e/e VLSFO’.

The LCA includes all life cycle stages from cradle to grave of ammonia fuel and VLSFO, i.e., production of fuel feedstock, fuel production, distribution and bunkering, as well as storage and combustion on board of the ship. This system boundary is often referred to as ‘well-to-wake’ (WtW).

The report includes two modelling approach: a consequential model and an attributional model aligned with the revised version of the Renewable Energy Directive (RED II) guidelines for renewable fuels of non-biological origin (RFNBOs).

This report is commissioned by A.P. Moller – Maersk and internal quality assurance has been ensured by inviting several relevant stakeholders to take part in the project scoping, data collection, and review of methods and assumptions. While the partners have contributed to validating the technical aspects, they have not participated in the interpretation of the results.

The project partners include: A.P. Moller – Maersk, Environmental Defense Fund Europe, Nippon Yusen Kabushiki Kaisha, CMA CGM, DFDS A/S, American Bureau of Shipping, MAN Energy Solutions, Svitzer A/S and Havenbedrijf Rotterdam N.V.

Appendix 9 – Marginal electricity mixes

Appendix 11 – Final review statement and itemized review report

Download full report here:

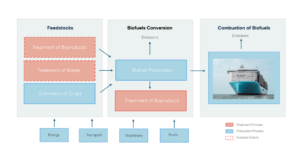

This report evaluates the sustainability of various used for biofuel production. The assessment covers ten different feedstocks, including Used Cooking Oil (UCO), Palm Oil Mill Effluent (POME) oil, Spent Bleach Earth (SBE) oil, soap stock acid oils, animal fats, Fatty Acid Methyl Ester (FAME) bottoms, brown grease, sewage, and food waste. The key aspects analysed for each feedstock include overall sustainability concerns, plausible global volumes, competing industries, potential risks of indirect land use change (iLUC), geographical dependencies, and potential mitigating actions.

Maersk has committed to a new fleet of dual-fuel vessels capable of running on alternative fuels like methanol, but sourcing the amounts of fuel needed to power them is no easy task. To inform their fuel strategy, Maersk needed to track the environmental performance of five different biofuels to compare and benchmark their sustainability.

The production of biofuels involves the use of land, feedstocks such as waste, crops or by-products, and large amounts of energy. This means that greenhouse gas (GHG) emissions and environmental impacts can vary significantly between biofuels, depending on what the fuel is made from, how it is processed and treated, and how much land was used in the process.

To achieve the flexible decision support required by Maersk, we delivered an LCA tool modelling the cradle-to-grave impacts of five different biofuels. The tool enables Maersk to consider different production pathways, feedstock inputs and regional markets where the fuel is produced, and to benchmark the GHG and non-GHG impacts from all combinations.

The LCA tool enables Maersk to determine the environmental impacts of any specific biofuel production. Because Maersk’s demand for renewable fuels is so significant, the project also included an estimation of the scalability and availability of each biofuel feedstock. This gives Maersk the market insight needed to choose the most sustainable and economically feasible renewable fuel solution.

Overall, the project gives Maersk unprecedented transparency into the climate risks, land-use change risks, and overall environmental sustainability performance of five biofuel alternatives in real time.

Energy and non-energy use of fossil carbon-based fuels and associated emissions have been extensively studied, but the retention and accumulation of fossil carbon in the technosphere are less understood. This study uses retrospective dynamic material flow modeling to map the flows related to fossil carbon in durables between the years 1995 and 2019 using monetary multi-regional supply-use tables for 1995–2019 and multi-regional hybrid supply-use tables for 2011. In 2011, 91% of the extracted fossil carbon flowed directly to the atmosphere, with 9% accumulating in the technosphere, primarily in con struction, manufacturing, and households. From 1995 to 2019, 8.4 Gt of fossil carbon (i.e., 30.8 Gt of CO2 equiv) accumulated in all human-made artifacts, with most remaining in use and some ending up in landfills, where decomposition exceeds 50 years. This study lays a critical foundation for future research focused on reducing fossil carbon reliance by curbing its inflow and slowing its throughput in the technosphere.

Hydrogen is widely recognized as an important future energy carrier because of its potential as a less polluting energy source with lower greenhouse gas (GHG) emissions. Several studies however have raised the issue, that a hydrogen economy would could impact the global climate system, by increasing the level of atmospheric hydrogen through leakages and due to the fact that hydrogen has been found to be an “indirect” GHG. This report provides a review of the latest technical and scientific knowledge on leakage rates in current and future hydrogen supply chains, as well as the global warming potential (GWP) of these emissions.

Various regional and international standards have been developed to measure the environmental impacts of transportation fuels and minimize greenwashing and misinformation regarding their sustainability. These frameworks offer standardized methods and calculation guidelines for fuel producers to be able to verify compliance with predefined sustainability criteria and to achieve greenhouse gas emission reduction targets.

However, significant inconsistencies exist among these standards in terms of methods, calculation rules, and default values assigned to specific fuels.

This study reviews and analyses five fuel standards, namely the European Renewable Energy Directive, the United Nation’s Carbon Offsetting and Reduction Scheme for International Aviation, the California Low Carbon Fuel Standard, the United States Renewable Fuel Standard, and the UK Renewable Transport Fuel Obligation. A qualitative analysis of the different schemes’ methods identified several discrepancies.

Overall, our findings demonstrate substantial variations in the methods and calculation rules prescribed by the five standards, often resulting in markedly different carbon intensity scores for the same fuel. Based on this analysis, we propose specific changes to the calculation rules to enhance harmonization and improve the accuracy in reflecting the environmental consequences of fuel production and use. These recommendations include that indirect land use changes are always included, and more transparency regarding the methods for calculating the fuel carbon footprint.

Amidst the energy transition and ongoing climate change, solar fuels are a sustainable solution for environmental-friendly energy supply for mobility, households and industry, for instance. A promising approach for solar fuel production is artificial photosynthesis (AP) – however, current systems are inefficient, expensive and unsuitable for industrial deployment. The EU project „SUNGATE“, aims to overcome these limitations by combining the principles of AP with photoelectrocatalysis and flow microreactor technology. As a result, the project will bring about the first modular full-cell continuous flow microreactor technology that requires sunlight as its only energy source as well as water and CO2 as simple, abundant feedstocks for conversion into solar fuels such as methanol and formate.

In contrast to state-of-the-art photoelectrochemical (PEC) technologies, SUNGATE will not use toxic or critical raw materials, and will combine efficient water oxidation catalysts with novel biohybrid CO2 reducing catalysts onto nanostructured electrodes to radically improve the efficiency of conversion. The unique modular and scalable design of SUNGATE technology will allow a flexible defossilised production of solar fuels for diverse applications ranging from decentralised energy infrastructure to closed carbon cycles for sectors that emit large amounts of CO2 (e.g. cement, steel and chemical industry).

SUNGATE aims to achieve proof of concept at TRL 5. This would result in a technology breakthrough that has the potential to secure the future global energy supply at an affordable cost and meets the central goal of the European Green Deal and the European Climate Law to achieve climate neutrality by 2050. The project’s interdisciplinary consortium of 12 academic, RTO and industry partners from six EU countries and Turkey will engage in the full validation of the technology, including life cycle assessment, as well as effective dissemination and knowledge transfer to accelerate industrial take up. SUNGATE (HE 101122061) received a total budget of about 4.9 million euros from the European Union’s Horizon Europe programme under the Grant Agreement 101122061and will run until September 30, 2027.

Under the coordination of the Fraunhofer Institute for Molecular Biology and Applied Ecology IME, the project has the collaboration of 11 partners from research and industry: Fraunhofer Institute for Microengineering and Microsystems IMM (Germany), Fraunhofer Institute for Silicate Research ISC (Germany), University of Warsaw (Poland), Institute of Chemical Research of Catalonia (Spain), University of Stuttgart (Germany), Ulm University (Germany), Ghent University, (Belgium), Tarsus University, (Turkey), 2.-0 LCA consultants, (Denmark), Danish Board of Technology, (Denmark) and Chemtrix BV, (Netherlands).

The study consisted of a consequential LCA of electricity produced at an average BeGreen solar photovoltaic (PV) park. Inventory data included materials, lifetime, maintenance, electricity production etc. The most significant impact categories were identified, and a detailed contribution analyses was provided for the three most relevant impact categories. The predominant hotspots and improvement potentials for the average BeGreen Solar Park were identified. This project was reviewed by a single expert reviewer, between October and November 2023, according to ISO 14044.

Limiting post-combustion emissions is one of the most urgent actions for environmental remediation. However, capture technologies face multiple challenges mostly due to the low concentration of pollutants, such as carbon dioxide (CO₂) or nitrogen oxides (NOₓ), making them highly inefficient. Additionally, even if successful, there are very few plausible uses for the captured pollutants, apart from long-term geological storage.

In the pursuit of a more sustainable future, SUPERVAL’s primary objective is to address these challenges simultaneously, investigating the viability of a technology capable of transforming the treatment of post-combustion gases to unlock the potential of carbon and nitrogen components by separating and transforming them into valuable resources.

SUPERVAL will design and realize an autonomous, solar-powered installation able to capture harmful emissions from flue gas, and valorise them as commodities for the chemical industry. The CO2 will be transformed into an organic, energy-rich molecule (formate). The NOx will be also captured and transformed, in combination with N2, into ammonia using the hydrogen obtained in the CO2 co-electrolysis processes. This integrated effort will offer the comprehensive capture and valorisation of carbon and nitrogen components in post-combustion emissions, thus limiting pollutants and resulting in added-value chemicals. The corresponding techno-economic analysis and life cycle assessment studies will help to shape the components and performance of SUPERVAL as a useful technological advancement in the search for zero net emissions.

SUPERVAL will be coordinated by the research institution Institut Catala d'Investigacio Química (ICIQ-CERCA) and will bring together a consortium of diverse organizations contributing their unique expertise and resources. The participating partners include: Orchestra Scientific. Universitat Politècnica de València – UPV, Consorzio Interuniversitario Nazionale per la Scienza e Tecnologia dei Materiali - INSTM UdR Messina, CASPE Laboratory. Forschungszentrum Julich, Technische Universiteit Eindhoven - TU/e. Vareser 96 and 2.-O LCA Consultants.

The aim of the project was to build a specific LCA model and Excel tool for MAVASOL to calculate the potential GHG emission savings from their sand recovery system (SRS) for dairy farms. This was done by comparing two alternative scenarios with and without the sand recovery system.